Solutions for Automotive Manufacturing Repetitive Tasks

Whether it’s bumpers, mufflers, A.C. units, drive shafts, doors, wheel hub assemblies, seats or body panels, the one common feature is that each part must be handled at least once at the manufacturers and every 30 to 60 seconds at the assembly plant.

Most high frequency handling involves lightweight parts in the 20 to 100 lb. range which, when occasionally lifted, can be accomplished manually, but 30 lb. every 40 seconds adds up to 21,600 lb. lifted per shift (over 10 tons).

A pneumatically controlled operator assist device suspended from a hoist or air balancer and traveling on lightweight low resistance cranes will reduce the strain and fatigue common to high rate assembly operations.

Starquip’s Mandate:

Each handling device is specifically designed to suit the product handled. Keep it simple, lightweight, easy to use and safe. These are the main design criteria. The seat manufacturers device and the auto assemblers door install device are only two of many specialty devices engineered by Starquip.

Starquip has worked extensively with many companies in the food and pharmaceutical industries, helping them upgrade ergonomic conditions within their facilities. Solving material handling challenges here involves more than just the special paint or explosion proof equipment we provide off the shelf and custom Stainless Steel operator lift assist devices including Vacuum Lifters, Roll & Drum Handling Equipment, Carts and more. Our experienced representatives can visit your facility to analyze the entire process to ensure complete, proper integration into your client's manufacturing framework.

When it comes to handling glass, we have done it. Starquip has provided vacuum lifters for automotive, architectural and construction glass. We have also converyed ray glass, fibreglass and broken glass.

If you have to pick it, turn it, roll it over, stand it up. install it or ship it out - we can help.

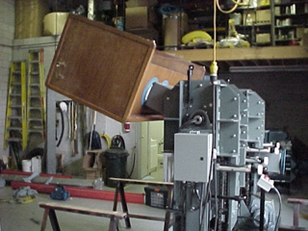

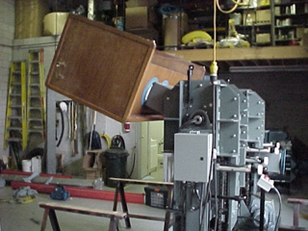

Large, heavy, awkward and fragile are the words that describe products in this industry. Starquip has handled loads as varied as oak desks and photocopier components.

We know how to move your materials safely and easily.

Starquip has worked extensively with many companies in the printing industry to help upgrade their ergonomic contitions in their facilities. Heavy roll or bundles of paper, dusty environments, fragile print rollers are typical in many printing plants. Don't have your workers reaching, bending or twisting with heavy materials - call us for low cost lifting and handing solutions.